Inventory management has a bigger impact on your practice than most people realize. It affects your cash flow, your margins, your team’s morale, and even the quality of care you deliver. When it runs smoothly, everything else does too.

Most practices assume their inventory is “fine.” After all, the shelves aren’t empty, right? But when you look closer — COGS creeping past benchmarks, meds expiring on the shelf, orders going out “just in case,” it becomes clear: there’s real money and time slipping through the cracks.

The good news? These problems are fixable. In this article, we’ll break down the most common inventory mistakes we see in vet clinics and how to tackle them. We’ll also show you where automation can do some heavy lifting, helping you reclaim time, improve margins, and avoid inventory chaos.

Mistake #1: Overstocking

What it is: Ordering more than you actually need, often “just in case,” or to qualify for a volume discount. On paper, it feels proactive. In practice, it’s tying up cash and filling your shelves with products that might expire before they’re ever used.

Consequences:

- Cash flow strain — money locked in shelves instead of working for your business.

- Increased holding costs — storage, spoilage, and depreciation all add up the longer products sit unused.

- Expired inventory — industry estimates show 1.5–2% of revenue is lost to products that go to waste.

Overstocking often comes from a place of good intentions: trying to be prepared, avoid stockouts, or get a better deal. But without real data to back those decisions, it becomes a silent drain on your clinic’s profitability.

How to avoid:

- Base ordering on actual usage data, not habit or hunches

- Maintain a lean, 2–4 week supply on most items

- Use ABC analysis to prioritize core, high-usage items

- Monitor turnover rates and cut back on slow movers.

📌 Inventory Allyhelps by calculating dynamic reorder points that adjust as your usage patterns change. It applies predictive algorithms to take the guesswork out of ordering — you can stock smarter, tie up less cash, and still feel confident your shelves are covered.

Mistake #2: Understocking and Stock-Outs

What it is: Running out of critical items right when you need them most, whether it’s a common antibiotic, anesthesia supplies, or that one item everyone assumes is always on hand.

Consequences:

- Missed revenue from delayed or canceled treatments

- Loss of client trust and perceived reliability

- Extra labor from emergency orders or supply runs

- Stress on staff who are left scrambling.

- Extra shipping charges for express delivery

Stock-outs aren’t just inconvenient; they directly affect patient care and profitability. And while they’re often treated as a fluke, they’re usually a symptom of inconsistent ordering habits or lack of visibility into what’s actually being used.

How to avoid:

- Set reorder thresholds and safety stock based on real usage

- Plan for seasonal patterns and upcoming promotions

- Create a backorder protocol (What’s the alternative? Who notifies clients? What’s the ETA?)

- Track supplier lead times and build buffers accordingly.

📌 Inventory Ally helps you stay ahead by sending proactive low-stock alerts and auto-recommending replenishment based on your specific consumption trends.

Mistake #3: Poor Tracking Systems

What it is: Still using sticky notes, a whiteboard, or shaking bottles to see what’s running low? You’re not alone, but relying on outdated methods like visual checks, notebooks, or legacy spreadsheets creates a major gap between what’s actually on hand and what your team thinks is on hand.

Consequences:

- Inventory shrinkage — from misplacement or unbilled use

- Stockouts or over-ordering — due to inaccurate quantity-on-hand estimates

- No audit trail — hard to trace when and where inventory errors or losses occurred

- Wasted team time — spent searching, counting, and double-checking.

Without reliable, up-to-date tracking, it’s almost impossible to make smart purchasing decisions or even know where your money is going.

How to avoid:

- Use inventory tracking tools in your PIMS or a dedicated inventory platform

- Run cycle counts regularly — weekly for high-turnover items, monthly for the rest

- Use barcode scanners, shelf tags, or even RFID where possible

- Assign expiration checks and spot audits to someone on a recurring schedule.

📌 Inventory Allyoffers centralized, real-time inventory tracking — even across multiple locations or decentralized purchasing environments. It simplifies audits, flags discrepancies, and supports usage-based forecasting so your numbers stay accurate and actionable.

Tired of flying blind with your inventory?

Inventory Ally helps you take control with usage-based forecasting, automated tracking, and actionable insights without disrupting your workflow.

👉 Learn how Inventory Ally works or Schedule a free demo.

Mistake #4: Not Using Data to Make Decisions

What it is: Many practices still order inventory the same way they always have — by habit, routine, or vendor suggestion. But without data to back those decisions, you risk consistently over-ordering slow movers and under-ordering high-demand items.

Consequences:

- COGS quietly creeping up

- Missed opportunities to negotiate pricing or phase out low-margin products

- Stock levels drifting further from what the clinic actually uses

- No visibility into performance of SKUs or suppliers.

If you’re not regularly reviewing usage and financial data, it’s easy for inefficiencies to pile up unnoticed.

How to avoid:

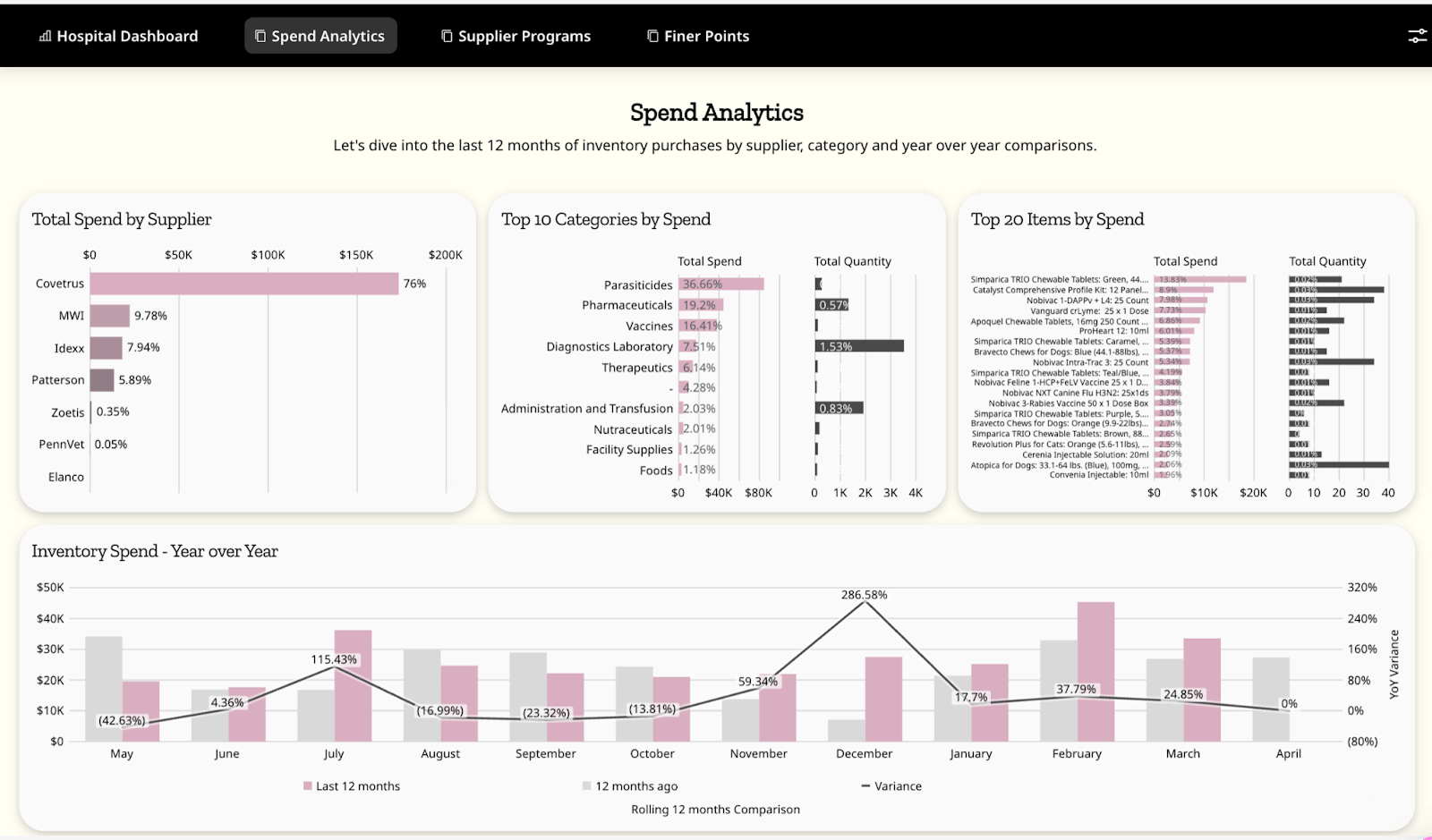

- Review usage and order history monthly

- Adjust min/max levels based on real trends, not just gut feeling

- Track COGS as a % of revenue (ideally ~20%)

- Flag and remove low-turnover products from auto-orders or switch to special-order status.

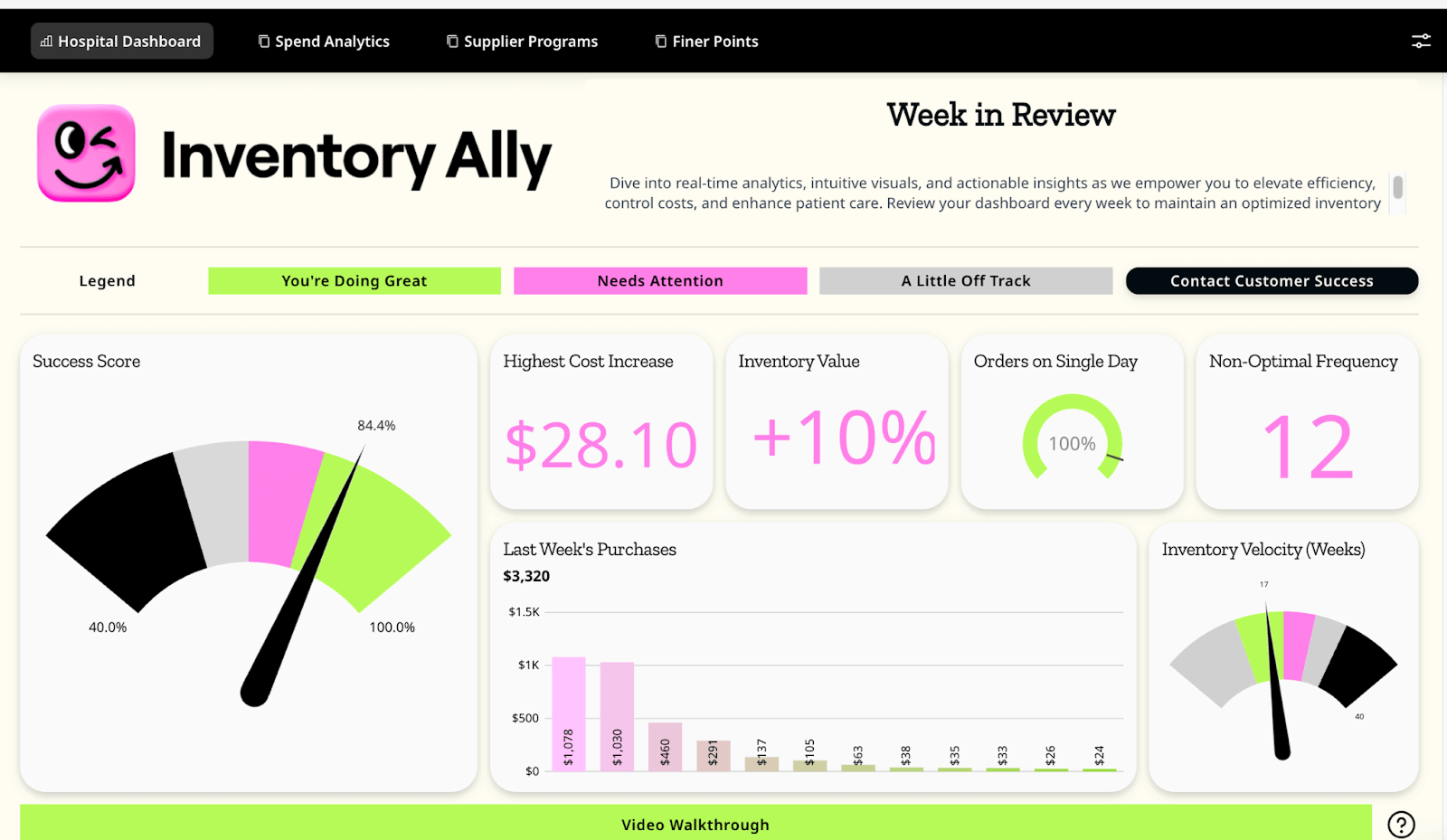

📌 Inventory Ally gives you clear, actionable data in one place, so you can make smarter decisions without digging through reports or second-guessing your numbers.

Mistake #5: Carrying Too Many Duplicate or Slow-Moving Items

What it is: It’s surprisingly common for clinics to stock multiple brands of the same medication or keep niche products “just in case.” Over time, this leads to bloated shelves full of items that rarely move, and might expire before they’re ever used.

Consequences:

- More inventory to track and manage

- Higher risk of expiry and shrinkage

- Tied-up cash in low-value or duplicate items.

An excessive formulary doesn’t just cost money. It adds complexity, increases human error, and clutters up your ordering process.

How to avoid:

- Build and maintain a core formulary

- Eliminate duplicate items unless medically necessary

- Use sales or usage reports to flag low-turnover SKUs

- Shift slow movers to special-order only where possible.

📌 Inventory Ally includes formulary optimization tools and real-time SKU performance tracking, helping you identify what to keep, what to cut, and where your inventory is working against you.

Mistake #6: Treating Inventory as a One-Time Setup

What it is: You did a big inventory overhaul — organized the shelves, built a formulary, maybe even ran a full count. Great start. But then… everything slowly drifted back to the old patterns.

Inventory isn’t a “set it and forget it” task. Usage patterns change. Vendors update pricing. New treatments come in, and old SKUs become obsolete. Without ongoing monitoring and adjustments, even the best initial setup becomes outdated fast.

Consequences:

- Reorder points no longer reflect real usage

- Formularies drift off-track as staff revert to personal preferences

- COGS creeps back up due to quiet inefficiencies

- You lose visibility as inventory practices revert to habit over process.

How to avoid:

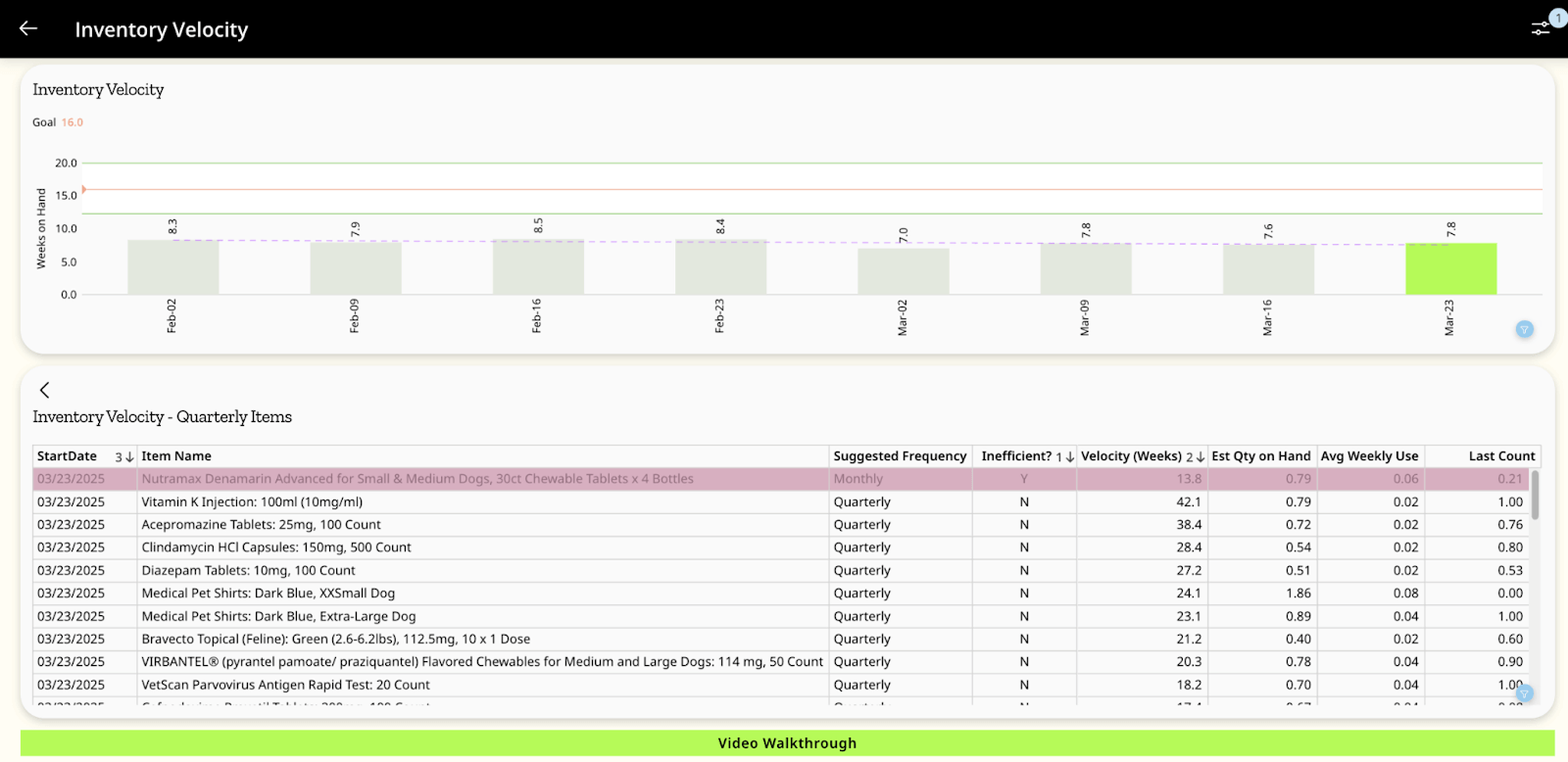

- Review inventory data monthly or quarterly to spot changes

- Revisit formulary compliance and update when new SKUs are introduced

- Set reminders to review reorder points and min/max thresholds

- Treat inventory as a living system, not a checklist.

📌 Inventory Ally automatically updates reorder points and usage forecasts based on real-time trends, so your inventory strategy evolves with your practice. Stay agile instead of reactive, and keep control as the system adjusts to your needs.

Mistake #7: Ignoring Financial Metrics and Price Increases

What it is: Inventory isn’t just about what’s on your shelf; it’s directly tied to your revenue and profitability. However, many clinics overlook key financial indicators like COGS, product margins, and whether all dispensed items are actually billed.

Consequences:

- Selling at a loss due to outdated pricing or cost increases

- Missed charges for products used but not invoiced

- Poor visibility into product profitability

- COGS creeping above industry benchmarks.

If you’re not tracking the right numbers or don’t have a way to connect inventory data to financial outcomes, it’s hard to know where the leaks are.

How to avoid:

- Monitor COGS regularly as a percentage of revenue

- Adjust markup and pricing when supplier costs change

- Reconcile usage vs. billing to catch missed charges

- Use tools that highlight margin gaps and underperforming items.

📌 Inventory Allytracks COGS trends, flags pricing inconsistencies, and makes it easier to align inventory use with billing, so you can tighten your margins and make more informed financial decisions.

Mistake #8: No Designated Inventory Owner

What it is: In some practices, inventory is “everyone’s job”, which usually means it’s no one’s job. Without clear ownership, tasks fall through the cracks, orders get duplicated or missed, and there’s no consistency in how inventory is managed.

Consequences:

- Double-orders or missed reorders

- Inconsistent processes across shifts or locations

- Lack of accountability when things go wrong

- Wasted time retracing steps or fixing preventable mistakes.

Even the best tools won’t help much if no one’s empowered to use them consistently.

How to avoid:

- Assign a dedicated inventory manager or point person

- Provide standard operating procedures (SOPs) and cross-training

- Give that person authority, tools, and reporting access to manage effectively

- Review inventory tasks and goals in weekly or monthly check-ins.

📌 Inventory Ally makes it easy for one person (or a team) to stay on top of inventory with role-based access, user-friendly dashboards, and real-time visibility into what’s happening across the clinic.

Mistake #9: Reactive Ordering Instead of Planning Ahead

What it is: Ordering only when something runs out, or nearly does. It’s a cycle many clinics fall into: staff spot a low item, place an order in a rush, and hope it arrives before it’s needed. The problem? This “fire drill” approach creates more stress than stability.

Consequences:

- Rush orders and high shipping costs

- Increased risk of stockouts if vendors are delayed

- More time spent chasing supplies instead of managing them

- Burnout for whoever gets stuck managing last-minute orders.

When you’re constantly reacting, you’re never really in control.

How to avoid:

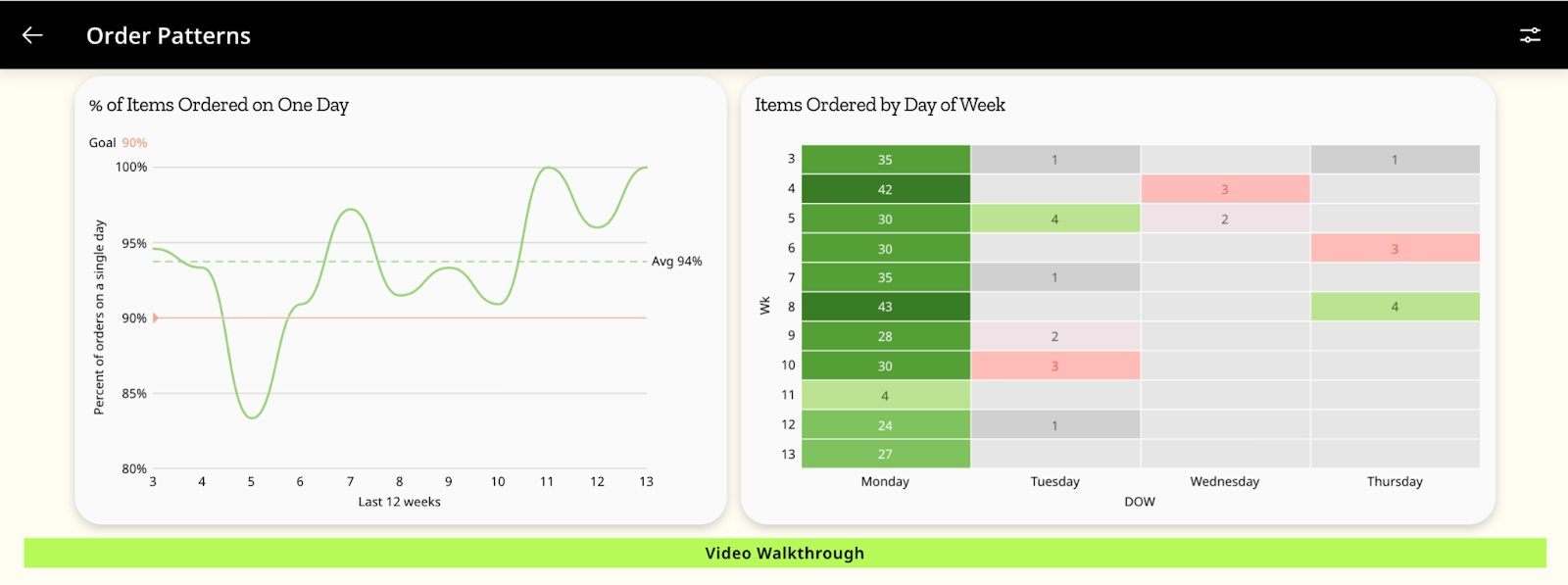

- Set a regular ordering schedule — weekly or biweekly

- Build a buffer based on vendor lead times and usage trends

- Plan ahead for seasonal demand, promotions, and known shortages

- Track restock windows so you’re ordering at the right time, not just the urgent time.

📌 Inventory Ally recommends replenishment timing based on real-time usage trends and vendor behavior, helping you stay ahead of demand without over-ordering or scrambling.

Mistake #10: Inefficient Purchasing and Vendor Management

What it is:

Ordering from too many vendors, chasing deals one product at a time, or not leveraging buying groups can leave your team spending more time — and money — than necessary. Without a system, purchasing becomes chaotic, inconsistent, and harder to track.

Consequences:

- Wasted time placing and reconciling multiple small orders

- Missed volume discounts and rebate opportunities

- Harder vendor relationships with no consistency or leverage

- Lack of visibility into total spend and performance.

Just like inventory needs structure, so does purchasing.

How to avoid:

- Consolidate vendors where possible

- Use a purchasing platform or group purchasing organization (GPO)

- Build long-term relationships with your key reps

- Track order frequency, cost trends, and vendor performance.

📌 Inventory Ally streamlines purchasing by centralizing order data, enabling bulk order planning, and supporting vendor integration.

Conclsuion

Across all ten of these mistakes, one theme keeps popping up: inventory issues are rarely about a single bad order — they’re about systems that haven’t kept up.

When inventory is treated proactively, managed by the right people, and guided by real data, the payoff is big: fewer stockouts, less waste, better margins, and a less stressed-out team.

Inventory Ally was built to support exactly that. With real-time tracking, smart forecasting, and automated replenishment, it gives your team the visibility and control needed to manage inventory with confidence.

👉 Inventory doesn’t have to be complicated

See how Inventory Ally compares to your current system — book a 15-minute walkthrough to get a feel for how it fits into your practice.

Further Reading

Want to dig deeper into inventory strategy, financial impact, or just sharpen your clinic’s workflow? Here are a few picks from the Inventory Ally blog we think are worth a read:

- A Practical Guide to Veterinary Inventory Management

A solid overview of how to streamline your inventory using cycle counts, usage-based ordering, and smarter stock tracking—without creating more work for your team. - The Hidden Costs of Poor Veterinary Inventory Management

Breaks down how messy inventory quietly chips away at margins, patient care, and team morale—and what to do instead. - Five Steps to a Financially Healthy Veterinary Practice

Connects inventory decisions to the bigger financial picture, from COGS and pricing to improving cash flow without cutting corners.