Most veterinary practices don’t think they have an inventory problem.

The shelves look stocked. Orders go out. The numbers in the PIMS look about right. If a syringe box runs low, someone catches it. And so, the logic goes — why fix what isn’t broken?

But there’s a big difference between something that works, and something that’s truly optimized.

Every practice develops its own rhythm for managing inventory — someone keeps an eye on the shelves, another checks prices before ordering, the techs mention when something’s running low. It’s not perfect, but it functions. And because you can pull up lists, review order history, and see numbers on a screen, it feels like you’re in control.

Here’s the problem: those numbers only show what was purchased or billed — not what’s actually being used, wasted, or quietly expiring in the back. Inventory is like an iceberg. What you see above the surface looks manageable. But beneath it lies a tangle of hidden costs: expired medications eating profit, overstock tying up cash that could go toward payroll or equipment, emergency orders placed at a premium because something critical ran out overnight.

These problems grow slowly, so they rarely feel urgent. Until one day, you realize you’ve been sitting on $8,000 worth of product that expired last quarter. Or your team is spending ten hours a week just trying to figure out what to order next.

In this article, we’ll break down the three main ways veterinary practices track inventory today — spreadsheets, PIMS, and dedicated inventory software — and show you where each one shines, where it quietly fails, and what “good” really looks like when inventory stops being a chore and starts driving profit.

Spreadsheets: The Old Reliable

Every practice starts here. Excel or Google Sheets feel safe: familiar, cheap, and endlessly customizable. You can color-code cells, build formulas, lock tabs so no one accidentally deletes the master order list. For a while, it works beautifully.

But as your inventory grows from a few dozen SKUs to a few hundred — or you add a second person touching the file — the cracks start to show.

Version chaos. One staff member updates the desktop copy while another edits the cloud version. By Friday, no one’s quite sure which numbers are current, so someone just picks the file that “looks right.”

Human error. A single mistyped quantity throws off weeks of ordering. Formulas break when someone inserts a row. Tabs disappear when someone’s computer crashes mid-save.

Zero automation. The spreadsheet can tell you what’s on hand right now, but it can’t tell you what’s about to run out, when you’ll need to reorder, or how much you actually used last month versus what you thought you used.

No forecasting. You’re working with static snapshots — counts from last Tuesday, an order placed three weeks ago. There’s no way to see trends, track usage rates, or anticipate seasonal shifts. You’re always looking backward.

No audit trail. When something goes wrong — an order gets duplicated, a count doesn’t match, inventory mysteriously disappears — there’s no way to trace what happened or who changed what.

The spreadsheet method rewards diligence but punishes distraction. Miss one update, and the whole system loses integrity. And because it’s reactive by nature — built for recording the past, not predicting the future — you’re always one step behind.

For very small, stable practices with a single person managing orders, this approach can still hold up. But for everyone else, it eventually becomes a burden requiring maintenance instead of the solution it started out as.

The truth is, most teams know this. They stick with spreadsheets not because they’re ideal, but because they’re familiar, they’re free, and switching feels like one more thing to figure out. Until one day, the cost of not switching becomes impossible to ignore.

PIMS: Great for Patients, Not for Products

Most practices trust their PIMS to handle everything — appointments, billing, reminders, medical records, and yes, inventory. On the surface, it makes perfect sense. You’ve already invested in the system, your team knows how to use it, and keeping everything in one place feels cleaner than juggling multiple tools.

And to be fair, your PIMS does track inventory. You can see what’s on hand, set reorder points, run reports. For many practices, that feels like enough.

The issue isn’t that your PIMS is bad at inventory — it’s that inventory was never its primary job.

Most PIMS are built around patient transactions. They’re designed to capture what was sold or billed, which works brilliantly for invoicing and financial reporting. But inventory management requires tracking what was actually used, regardless of whether it hit a client record.

Every syringe pulled for a procedure that didn’t get charged. Every pair of gloves used during cleanup. Every vial opened but only partially administered. None of that gets captured if it’s not tied to a billable event — and over time, those small omissions add up.

Then come the practical challenges:

Manual reorder points. You have to set thresholds for every single item — and update them constantly as prices shift, usage patterns change, or pack sizes vary. It’s doable, but it’s tedious, and it assumes someone has the bandwidth to stay on top of it.

Reports that show transactions. Your PIMS can tell you what was invoiced last month — but without constant upkeep, the “quantity on hand” figure drifts farther and farther from reality. If your staff forgets to post a charge or substitutes one product for another without updating the record, your numbers slip even more out of sync.

No predictive insight. It tracks history, not trends — leaving your team reactive when it should be proactive.

Reconciliation becomes a chore. When discrepancies show up (and they will) you’re left manually cross-referencing invoices, physical counts, and transaction logs to figure out where things went sideways.

None of this means your PIMS is failing you. It’s doing exactly what it was designed to do — manage client relationships and patient care. But its inventory tools were built with a retail mindset: a simple “one bought, one sold, one replaced” model. Veterinary medicine is different — you consume products to deliver care, not just to sell them — which makes tracking and replenishment far more complex than retail-style inventory can handle.

In short, your PIMS gives you snapshots when what you really need is foresight. It tells you what happened, but it can’t help you decide what happens next.

Dedicated Inventory Software: Built for the Job

If spreadsheets are makeshift and PIMS are multi-purpose, dedicated inventory software is purpose-built. It’s designed from the ground up to do one thing exceptionally well: manage inventory.

The difference is in philosophy. Instead of tracking transactions after they happen, dedicated software tracks behavior as it unfolds. It learns how your practice actually uses supplies: which items move quickly, how demand shifts with seasons or promotions, what patterns repeat month after month. The result isn’t a static product list but a living system that anticipates your needs before you have to think about them.

Here’s what that looks like in practice:

Forecasting and automation. The system knows when to reorder before you do, based on your actual consumption history — not arbitrary par levels someone set six months ago and never updated. It adjusts recommendations as your usage changes, so you’re never caught off guard.

Complete visibility. Every item gets monitored — from consumables and pharmaceuticals to retail products and surgical supplies — even the things that never show up on a client invoice. You finally see the full picture of what’s moving, what’s sitting idle, and where your money is actually going.

Precision without the manual work. No more weekly counts or “guesstimate” orders. Replenishment happens on a predictable cycle, driven by data rather than gut feeling. Your team stops firefighting stockouts and starts operating from a place of confidence.

Insights that drive decisions. You can see exactly how fast inventory turns over, which products tie up cash flow, and where small adjustments could free up significant capital. It transforms inventory from a necessary headache into a tool for strategic planning.

The fundamental shift is this: spreadsheets and PIMS keep you in a cycle of reacting — scrambling when something runs out, reconciling after discrepancies appear, ordering when the shelf looks empty. Dedicated inventory software helps you predict and plan. It turns inventory from a cost center you manage into an operational advantage that runs itself.

That’s where you stop working for your inventory and start letting it work for you.

Where Inventory Ally Fits In

👉 Learn how Inventory Ally works

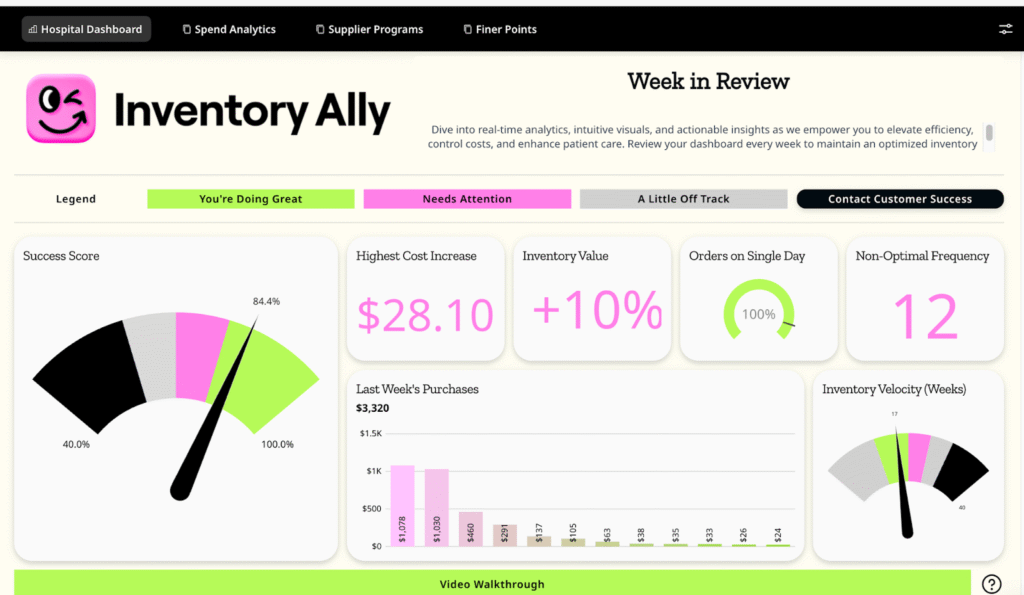

If you’re reading this and realizing your current system might be “working fine” — but only on the surface — that’s exactly where Inventory Ally comes in.

Here’s the thing about general inventory software: it’s built for retail, manufacturing, or warehousing. It understands SKUs and reorder points, but it doesn’t understand veterinary medicine. It doesn’t know that flea and tick preventatives spike in spring, that your surgical supply usage depends on case mix, or that vaccine inventory needs to account for multi-dose vials and cold chain management.

Inventory Ally was built specifically for veterinary practices, by people who’ve worked in your shoes. It’s not a replacement for your PIMS — it’s the intelligence layer that makes your existing system smarter. It plugs the gap between what your PIMS tracks (transactions) and what you actually need to manage (consumption).

What that means in practice:

The automation learns from your practice. Inventory Ally analyzes your real order history and usage patterns to understand what’s normal for you. It knows that your orthopedic surgery days consume more supplies. It recognizes seasonal shifts in heartworm preventatives. It adapts to your specific consumption habits and continuously fine-tunes its recommendations over time.

You get real-time visibility. Not just “how many units are on hand,” but insights like: which products are tying up the most capital, what’s about to expire, where your purchasing patterns have changed, and when it’s actually time to reorder — based on your pace, not a generic formula.

The ROI happens fast. Many practices recoup years of service costs in the first quarter just by eliminating waste, avoiding rush orders, and right-sizing their stock levels. But the bigger return is harder to quantify: the relief of knowing your inventory runs itself, so you can focus on patients instead of spreadsheets.

Continuity without disruption. Because all data and processes live in one place, Inventory Ally keeps your inventory running smoothly even when key people are away — whether for PTO, medical leave, or other responsibilities. Part-time or remote managers can stay productive, and practice owners can easily check in on key numbers from anywhere, ensuring consistency and confidence without extra effort.

In other words: while your PIMS records what happened, Inventory Ally helps you decide what happens next.

The Hidden ROI of Getting It Right

When practices think about upgrading their inventory system, the first question is usually about cost. What will this cost us? But the better question is: what is the current system costing you?

The real value of getting inventory right isn’t just reducing expenses — it’s reclaiming time, gaining confidence, and building operational stability. And while those benefits sound abstract, they show up in very concrete ways.

Hours back in your week. Practices using dedicated software often go from spending 5–10 hours a week on manual counts, reconciliations, and order placement to spending just 30 minutes. That’s the equivalent of hiring an invisible assistant who never takes a day off and never forgets to hit “save.”

Lower cost of goods sold. Even modest efficiency gains — 10% less overstock, fewer emergency orders, tighter reorder cycles — can free up tens of thousands of dollars annually. For a practice spending $300K on inventory each year, that’s $30K back in the budget for payroll, equipment, or continuing education.

Cash flow unlocked. Instead of thousands of dollars sitting idle on shelves (in the form of overstock or slow-moving items), that capital becomes available for higher-priority investments. Your money starts working for you instead of gathering dust in the back storage room.

Team morale lifted. When your staff stops firefighting stockouts and reconciling mystery discrepancies, they can focus on what they actually signed up for: patient care. No more “who placed the order?” or “why are we out again?” moments eating into the day.

Most practices using Inventory Ally recover the cost of five years of service within the first twelve weeks — simply through smarter purchasing and reduced waste. But the return that’s harder to measure might actually be more valuable: the quiet relief of knowing your system runs itself, so you can get back to practicing medicine.

How to Choose the Right Method for Your Practice

| Scenario | Best Fit | When It Works | When It Starts Breaking |

|---|---|---|---|

| Simple & solo • Small, steady inventory list • One person handles orders • Occasional errors are tolerable | Spreadsheet | Quick setup and low cost. Great for clinics with predictable usage and one decision-maker. | As soon as more people get involved or stock volume grows — updates become messy, errors multiply, and version control fails. |

| Moderate & multi-user • Rely heavily on PIMS • Multiple staff order or use items • Numbers don’t match what’s on shelves | PIMS-based tracking | Convenient for lightweight tracking inside your main system. Keeps things connected to patient care. | Designed for patients, not products. Lacks forecasting, cost visibility, and detailed reporting. |

| Complex & data-driven • Need trend insights and forecasts • Track by category, location, or time • Want fewer surprises and better planning | Dedicated inventory software | Scales with your practice. Automates reordering, forecasting, and reporting for proactive control. | None — this is the long-term solution once operations outgrow manual tools. |

There’s no universal answer for which system is “right.” What works depends on how your practice operates, how many people touch inventory, and how much manual management you’re willing to absorb.

Here’s a quick gut check:

If you…

- Have a small, steady inventory list

- Are the only one placing orders

- Can tolerate a few errors or delays here and there

→ Spreadsheets can still work. Just know they don’t scale well, and what feels manageable today might not in a year or two.

If you…

- Depend on your PIMS for nearly everything

- Have multiple people adding, using, or ordering items

- Feel confident in your system but can’t quite explain why the numbers never match reality

→ You’ve likely outgrown your PIMS’s inventory tools. It’s doing its job for patient care, but it wasn’t built to manage products at this level of complexity.

If you…

- Want to see usage trends and predict needs before they become urgent

- Need visibility across categories, locations, or time periods

- Are tired of firefighting and doing mental math every time you place an order

→ It’s time for dedicated inventory software. The shift from reactive to predictive changes everything.

Before you decide, ask yourself three questions:

How many hours a week does your team spend managing inventory? If the answer is more than one or two, that’s time (and money) you’re losing to a system that should be running in the background.

How often do you discover waste, overstock, or missed charges? If it’s a regular occurrence rather than a rare surprise, your current method isn’t giving you the visibility you need.

When was the last time your inventory system surprised you — in a good way? If you can’t remember, that’s a sign it’s working for you to manage rather than working to help you succeed.

The right system isn’t about the size of your practice — it’s about clarity. It should give you the confidence to make inventory decisions based on data, not guesswork.

From Tracking to Thriving

Most veterinary teams don’t need convincing that inventory matters — they just need proof that it can be easier.

The difference between a practice that’s “fine” and one that’s truly profitable often comes down to how well they manage what they already own. When you trade guesswork for insight, late orders for automation, and static lists for live intelligence, inventory stops being something you manage and starts being something that manages itself.

Inventory Ally was designed to make that shift simple. Not another system to wrangle, but a tool that helps you reclaim time, uncover hidden profit, and run a calmer operation — so you can get back to the work that actually matters.

Because the best practices don’t just track inventory. They master it.

Lessons from Real Practices

Want to see how other practices are handling their inventory challenges? Check out the case studies: