When inventory is set up well, it fades into the background. Orders arrive on time, everything is where you expect it to be, and you spend less time putting out fires. The challenging part is knowing whether you’ve built a solid system or simply adapted to ongoing problems.

Below are seven signs your veterinary inventory is set up for success. If you recognize most of them in your practice, you’re doing something right. And that’s worth celebrating.

Sign 1: You’re Not Hunting for Basic Supplies

Picture this: Your vet tech needs syringes for a patient, and instead of opening the supply cabinet and grabbing what they need, they’re digging through three different drawers, checking two storage rooms, and eventually texting the team, “Does anyone know where the 3ml syringes went?”

If your team can confidently find what they need, when they need it, without delays or frustration? That’s a win.

Good inventory management means having clear organization, consistent placement, and real-time visibility into stock levels. This might look like labeled bins with minimum/maximum quantities marked, designated storage zones for different categories (medications, surgical supplies, diagnostics), or a software that keeps track of everything. The key is consistency. When every team member can find what they need without asking, you’ve built a system that works.

Sign 2: Your Team Isn’t Stressed About Running Out

There’s a unique kind of stress that comes with not knowing if you’ll have what you need for tomorrow. Will we have enough suture material? Are we low on anesthesia? Did anyone remember to reorder flea preventatives?

When inventory is working well, your team operates with confidence. They know the supplies will be there because there’s a system in place.

That system can look like weekly visual checks of critical items, automated low-stock alerts, reliable reorder schedules that account for lead times, or a shared digital “want list” so requests don’t get lost — especially useful for teams who rotate between locations, house calls, or farm visits.

Whatever the method, the result is the same: your team can work without disruption, knowing the supplies they rely on will always be there.

Sign 3: You Actually Know What You’re Spending

Inventory costs can sneak up on you. One month you’re ordering the usual supplies, and the next month your expenses have somehow ballooned without a clear explanation. Sound familiar?

When inventory is managed well, your COGS is predictable and consistent. You’re not dealing with surprise invoices or wondering where all your money went. You have visibility into what you’re spending, why you’re spending it, and where there might be opportunities to optimize.

This means tracking more than just totals. Look at spending by category (medications vs. supplies vs. consumables), by vendor, and by month. Are certain items eating up a disproportionate amount of your budget? Are you taking advantage of bulk discounts where it makes sense? Do you know which products have the best margins? When you can answer these questions confidently, you’re managing inventory strategically, not just reactively.

Sign 4: Expired Products Are Rare, Not Regular

We’ve all heard the story: A team member pulls a medication for a patient only to discover it expired months ago. Now they’re scrambling to find a replacement, delaying treatment, and the practice is out the cost of that wasted product.

If this happens frequently, it’s a red flag that you’re over-ordering or not rotating stock properly. But if expired products are a rarity in your practice? That’s a sign your inventory is right-sized and well-managed.

Good inventory management means ordering what you’ll actually use, not stockpiling “just in case.” It means implementing first-in-first-out (FIFO) practices, regularly checking expiration dates during cycle counts, and adjusting order quantities based on actual usage rather than gut feeling. Consider organizing your storage by expiration date, with older stock always in front. And review your par levels regularly for slow-moving items. Just because you’ve always ordered a certain quantity doesn’t mean it’s still the right amount.

Sign 5: Ordering Takes Minutes, Not Hours

Remember when ordering inventory meant manually checking stock levels, calculating reorder quantities, cross-referencing vendor catalogs, and compiling everything into multiple orders across different suppliers? That process could easily eat up 4-8 hours of your week.

When inventory is working efficiently, ordering becomes quick and straightforward. You’re not starting from scratch every time. You have a clear process, standardized reorder points, and a streamlined workflow that turns what used to be a day-long ordeal into something manageable.

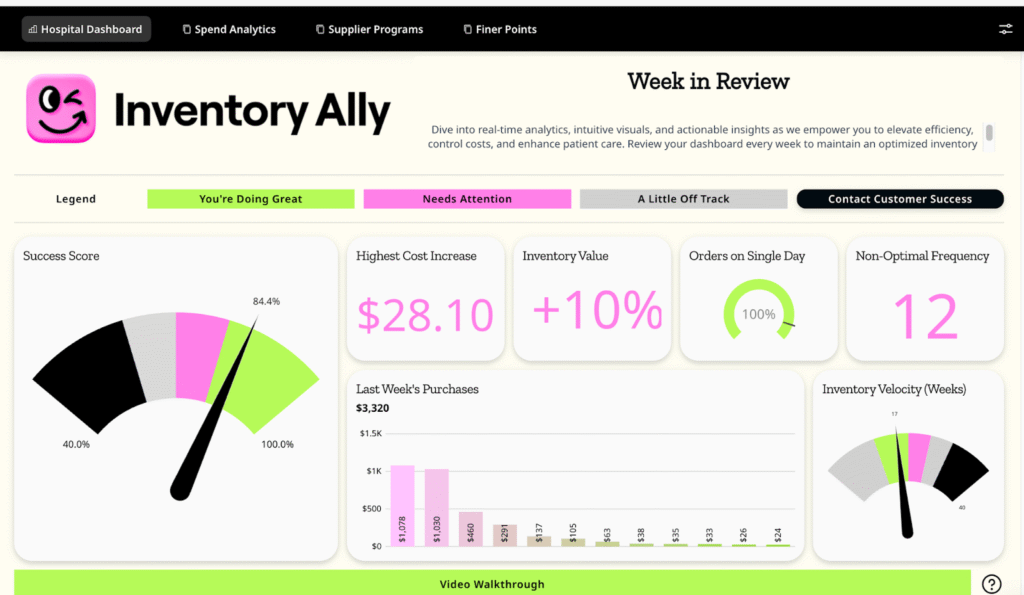

This is one area where automation can make a dramatic difference. When we built Inventory Ally, we focused on this exact pain point: taking the hours of manual work out of ordering. The system generates optimized order lists based on historical usage and current stock levels, categorizes items by replenishment frequency, and can even submit orders directly to suppliers. What used to take 4-8 hours gets reduced to 15-30 minutes of weekly review.

But even with a well-organized manual system — standardized checklists, clear par levels, and a consistent schedule — you should be spending significantly less time on ordering than you might think is normal.

Sign 6: You’re Making Decisions Based on Data, Not Guesswork

“I think we need more of this.” “It feels like we’re going through that faster than usual.” “Let’s just order extra to be safe.”

These are the phrases of inventory management by gut feeling. And while experience and intuition have their place, they’re not a substitute for actual data.

When inventory is working well, you’re making decisions based on real information: usage rates, seasonal trends, purchasing patterns, and historical data. You know what you’re using, when you’re using it, and how much you need, not because you’re guessing, but because you have the visibility to see it clearly.

Start by tracking basic metrics: How much of each item did you use last month? Last quarter? What about this time last year? Are there seasonal patterns (flea and tick products in spring, heartworm preventatives before summer)? Which items have the highest turnover vs. which sit on shelves? Even a simple spreadsheet tracking monthly usage can reveal patterns that change how you order. The key is consistency in tracking and regularly reviewing what the data tells you.

Sign 7: Your Inventory Adapts to Your Practice (Not Vice Versa)

Here’s a common scenario: Your practice grows. You add a new service line. The seasons change and certain products are suddenly in higher demand. A new veterinarian joins your team and has different preferences for certain medications or supplies.

If your inventory system can’t flex with these changes, you end up either drowning in products you don’t need or scrambling to keep up with new demand. But when inventory is working well, it adapts with you.

Good inventory management accounts for seasonality (hello, flea and tick season), adjusts to practice growth, and responds to shifts in services offered. It doesn’t force you to work around its limitations, it works around yours.

This means building in regular review periods (quarterly is a good cadence) where you look at what’s changed and adjust your par levels, reorder points, and vendor relationships accordingly. It means staying alert to trends in your own data. Did a new doctor join and suddenly your isoflurane usage doubled? Time to adjust. Did you start offering more dental procedures? Your dental supply orders should reflect that. A system that works is one that evolves as your practice evolves.

Celebrate What’s Working And Keep Building

So, how many of these signs are you checking off?

If you’re hitting most of them, take a moment to appreciate that. Managing inventory well in a veterinary practice is no small feat, and if you’ve built a system that’s reliable, efficient, and stress-free, that’s something to be proud of.

And if you’re not quite there yet? Now you know what’s possible. Every practice is different, and what works for one might not work for another. But whether you’re managing manually, using spreadsheets, or leveraging a tool like Inventory Ally to automate the heavy lifting, the goal is the same: an inventory system that works for you, not the other way around.

Because when inventory is really working, it fades into the background. It stops being a source of stress and starts being what it should be: a foundation that supports better patient care, a happier team, and a more profitable practice.

Ready to see what good inventory management can look like for your practice?

If you’re not checking all these boxes yet but want to get there, Inventory Ally can help. It is designed by veterinary professionals who understand the unique challenges you face. We automate the time-consuming tasks, provide real-time visibility into your stock, and continuously learn and adapt to your practice’s needs.